The global logistics and warehouse sector is experiencing unprecedented growth, with food packing positions emerging as indispensable pillars of the supply chain. These roles are critical to ensuring that food products reach consumers in optimal condition, balancing efficiency, safety, and quality at every step. In this article, we’ll delve into the multifaceted world of warehouse food packing jobs, covering key responsibilities, essential competencies, industry trends, and pathways for professional advancement.

Navigating Warehouse Packaging and Shipping Dynamics

Warehouse food packing is far more than simply placing products into boxes—it’s a strategic component of the broader shipping ecosystem. In today’s on-demand retail landscape, where grocery delivery and online food purchases are mainstream, packers play a vital role in preparing items for transit, verifying package labels for accuracy, and safeguarding products against damage during shipping. This requires a sharp understanding of logistics workflows, from order processing to final dispatch.

Modern warehouses are equipped with cutting-edge tools designed to streamline operations, and food packers must be proficient in leveraging these technologies. From inventory management software that tracks stock levels in real time to automated packing stations that accelerate throughput, technical literacy is a key asset. Additionally, effective teamwork and communication are non-negotiable: packers collaborate with inventory clerks, shipping coordinators, and quality inspectors to meet tight deadlines without compromising on standards. As consumer demand for fast, reliable delivery grows, the value of skilled food packing professionals continues to rise.

Mastering Food Packaging Equipment and Technology

The right equipment is the backbone of safe and efficient food packaging, and warehouse roles demand familiarity with specialized machinery tailored to food-specific needs. Food packers regularly operate tools such as automated bag sealers, vacuum packaging machines for perishables, conveyor systems that transport products between workstations, and carton formers that assemble packaging on demand. Proficiency with these devices not only boosts productivity but also ensures that food retains freshness, prevents contamination, and adheres to packaging regulations.

Technological innovation is reshaping the industry, with advancements like smart sensors that monitor packaging integrity and AI-powered systems that optimize packing layouts to reduce waste. Workers who stay abreast of these developments—whether through on-the-job training or self-directed learning—gain a competitive edge. Understanding equipment maintenance basics also minimizes downtime, as quick troubleshooting of minor issues can keep operations running smoothly. For career-focused individuals, expertise in emerging technologies opens doors to specialized roles such as equipment supervisors or technical trainers.

Prioritizing Quality Control in Food Packaging

Quality control is non-negotiable in food packing, where even small oversights can have far-reaching consequences for consumer health and brand reputation. Warehouse packers are frontline guardians of quality, tasked with following strict protocols to ensure every product meets safety and regulatory standards. This includes inspecting packaging for tears or defects, verifying that expiration dates and nutritional labels are clearly displayed and accurate, and confirming that sealing is secure to prevent spoilage or contamination.

Attention to detail is a critical soft skill for this role—packers must remain vigilant, as overlooked issues like improper sealing or mislabeling can lead to foodborne illnesses or product recalls. Employers typically provide comprehensive training on quality assurance processes, including adherence to FDA (or regional equivalent) guidelines and company-specific standards. By upholding rigorous quality control measures, food packers not only protect consumers but also reinforce trust in the brands they represent.

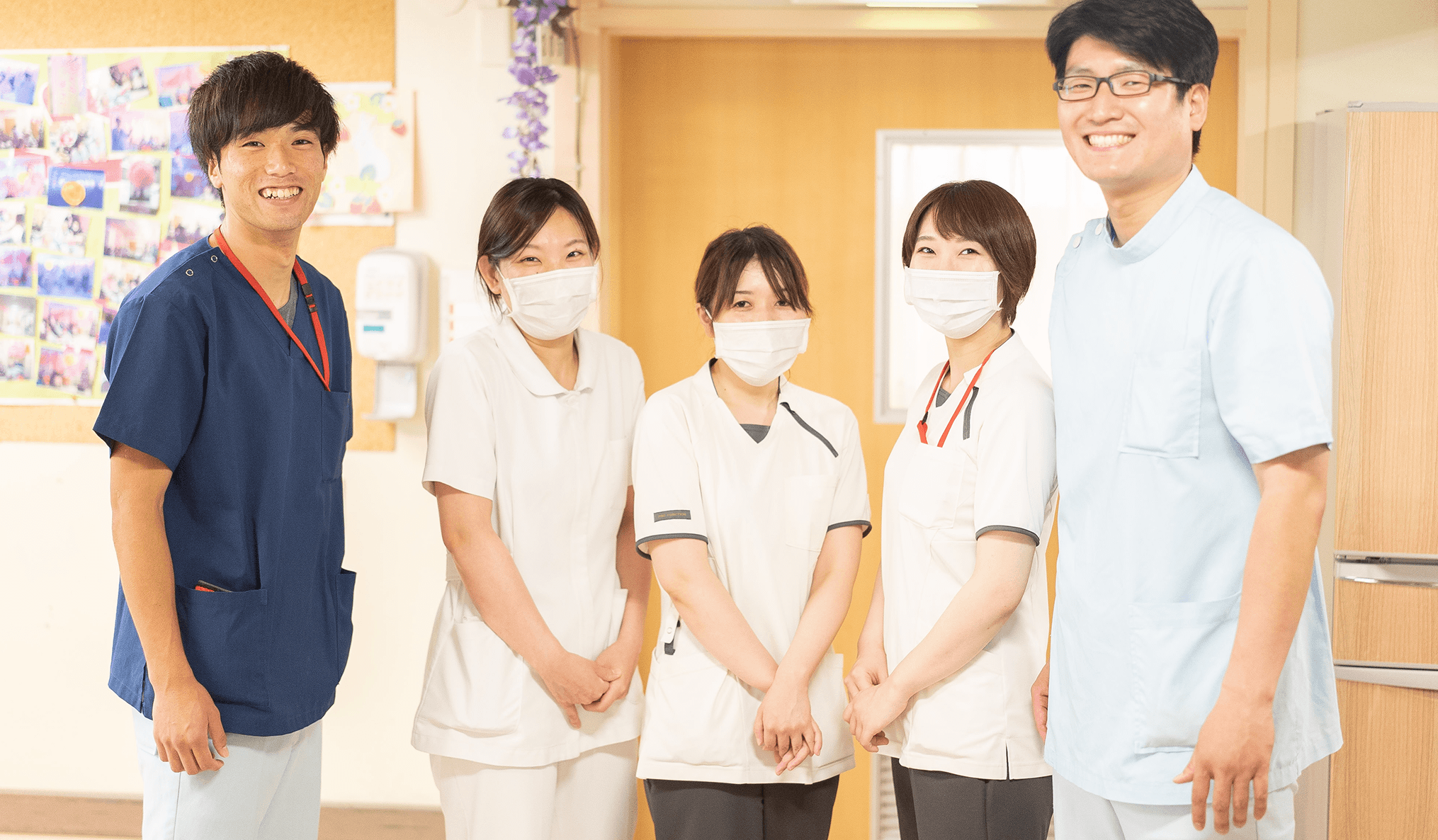

Upholding Health and Safety Standards in Food Handling

Warehouses handling food products adhere to strict health and safety protocols to protect both workers and consumers. Food packers must be trained in proper hygiene practices, such as frequent handwashing, using disposable gloves and hairnets, and avoiding cross-contamination between raw and packaged items. Physical safety is equally important: warehouse work often involves lifting heavy boxes, standing for extended periods, and operating machinery, so training in safe lifting techniques, slip-and-fall prevention, and equipment safety is mandatory.

Employers foster a culture of safety through regular audits, toolbox talks, and access to protective gear (e.g., non-slip shoes, cut-resistant gloves). Workers are encouraged to report hazards—whether a leaky container, malfunctioning equipment, or unsafe workspace conditions—without hesitation. A strong commitment to health and safety not only reduces the risk of accidents and liabilities but also creates a positive work environment where employees feel valued and protected.

Charting Career Growth in Warehouse Food Packing

Food packing jobs in warehouses are far from dead-end roles—they offer clear pathways for career advancement for ambitious individuals. Entry-level positions provide a foundational understanding of warehouse operations, and many employers offer structured traineeships, mentorship programs, and cross-training opportunities. For example, a packer might transition to roles in inventory management, shipping coordination, or quality control with experience.

Specialization is another route to growth: workers can pursue certifications in areas like food safety (e.g., HACCP certification), logistics management, or advanced machinery operation. These credentials enhance resumes and qualify candidates for supervisory or managerial roles, such as packing team leads, warehouse supervisors, or supply chain coordinators. As the industry expands, professionals with a mix of hands-on experience and specialized knowledge are in high demand, with opportunities to advance into regional management or even corporate logistics roles.

Contributing to Efficient Food Distribution Networks

Food packing is a linchpin in the global food distribution chain, connecting production facilities, warehouses, and end consumers. Packers must understand how their work impacts the broader supply chain—efficient packing reduces transit time, minimizes waste from damaged goods, and ensures that perishable items reach consumers before expiration. This requires familiarity with distribution workflows, including order prioritization (e.g., expediting fresh produce), batch processing, and coordination with shipping carriers.

Modern distribution relies on precision and timing, and packers play a key role in maintaining workflow efficiency. By staying informed about inventory levels, order volumes, and delivery schedules, they can adjust their processes to avoid bottlenecks. For example, pre-packing high-demand items during off-peak hours or collaborating with inventory teams to restock fast-moving products ensures that orders are fulfilled quickly. In turn, this efficiency boosts customer satisfaction and loyalty, reinforcing the warehouse’s role as a trusted partner in the food supply chain.

Embracing Sustainable Food Packaging Practices

Sustainability has become a defining trend in food packaging, driven by consumer demand for eco-friendly options and global efforts to reduce waste. Warehouse food packers are increasingly involved in adopting sustainable practices, such as using biodegradable packaging materials (e.g., plant-based plastics, paper-based wraps), minimizing excess packaging, and sorting materials for recycling. Many employers provide training on sustainable packaging techniques, encouraging workers to consider the environmental impact of their choices.

Beyond meeting consumer expectations, sustainable packaging offers tangible benefits for companies: it reduces material costs, lowers carbon footprints, and enhances brand reputation as an environmentally responsible organization. For workers, familiarity with eco-friendly practices is a valuable skill that sets them apart in the job market, especially as more companies prioritize sustainability. Whether it’s optimizing packaging sizes to reduce waste or advocating for reusable packaging solutions, food packers play an active role in shaping a greener supply chain.

Investing in Training and Skill Development

Continuous learning is essential for success in warehouse food packing, as the industry evolves with new technologies, regulations, and consumer demands. Employers often invest in their workforce through in-house training programs, online courses, or partnerships with vocational schools to teach new skills—from operating advanced machinery to understanding updated food safety regulations. Workers who take initiative to expand their knowledge—whether through self-study, industry workshops, or certification programs—are more likely to advance and thrive.

Key skills to develop include technical proficiency with emerging tools, problem-solving (e.g., addressing packaging bottlenecks), and adaptability (e.g., adjusting to new sustainability standards). Soft skills like time management, attention to detail, and teamwork are equally important, as they enable packers to work efficiently in fast-paced environments. By prioritizing skill development, individuals not only enhance their job satisfaction but also contribute to their employer’s ability to meet high standards of safety, quality, and efficiency.

In conclusion, warehouse food packing jobs offer stable, rewarding careers with room for growth in a thriving industry. From mastering cutting-edge technology to upholding safety and sustainability standards, these roles require a unique blend of technical skills, attention to detail, and adaptability. As the logistics sector continues to expand, workers who embrace learning, prioritize quality, and align with industry trends will find abundant opportunities to build successful, long-term careers in food packing and beyond.